Aerotrope have over 30 years’ experience in designing innovative wind turbine configurations from kilowatt to multi-megawatt scales; one-bladed to multi-rotors, both HAWT and VAWT configurations.

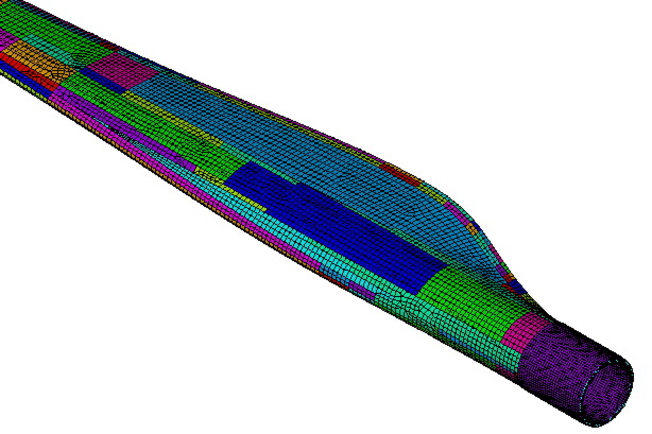

We have direct and recent experience in helping a client review their turbine’s general arrangement, leading to the definition of a proof-of-concept machine. We then carried out research into potential volume manufacturing techniques for future full-scale components e.g. pultruded/extruded blades as inputs to the overall cost model. Following this, we established the Basis of Design of the machine and produced load case documentation. We also performed both outline and detail design of the rotor, support structures and tower. This included conceptual design studies on alternate foundation options. All of the above required design in fibre-reinforced composites, steelwork and aluminium. As well as producing full manufacturing drawings and specifications, we also provide trial assembly and on-site erection methodologies.

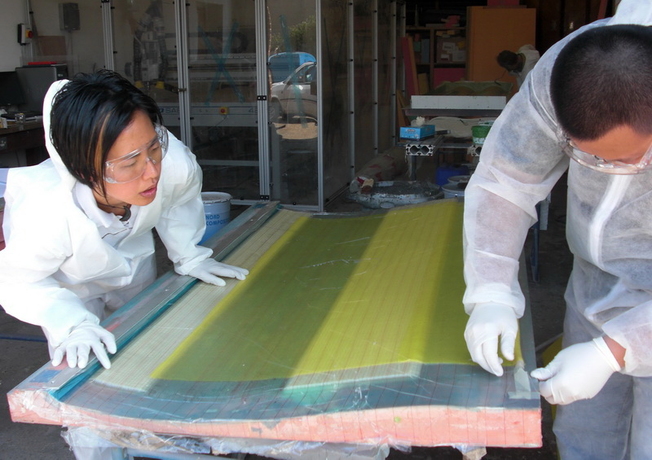

We advise on all aspects concerning the manufacture of turbine blades, moulds as well as designing reliable and efficient test rigs. Our design approach integrates aerodynamic and structural design to achieve the lowest Levelised Cost of Energy (LCOE). We assist our clients with concept selection, aerodynamics and structural design, test specification and test results correlation. Our extensive experience with FMEA methods, Root Cause Analyses and failure investigations is intrinsic to our engineering process from design, through manufacture, testing and certification to commissioning.

With regards to novel wind turbine configurations: We offer optimization of aerodynamic performance and an accurate cost-benefit analysis early in the process. New clients often engage us in the feasibility study of a new wind turbine design or in the design review of an existing product.